In the intricate world of textile manufacturing, one material stands out for its foundational role and adaptability: POY yarn. An acronym for Partially Oriented Yarn, this synthetic filament is a cornerstone in the production of high-performance textiles, prized for its balance of strength, elasticity, and transformation potential.

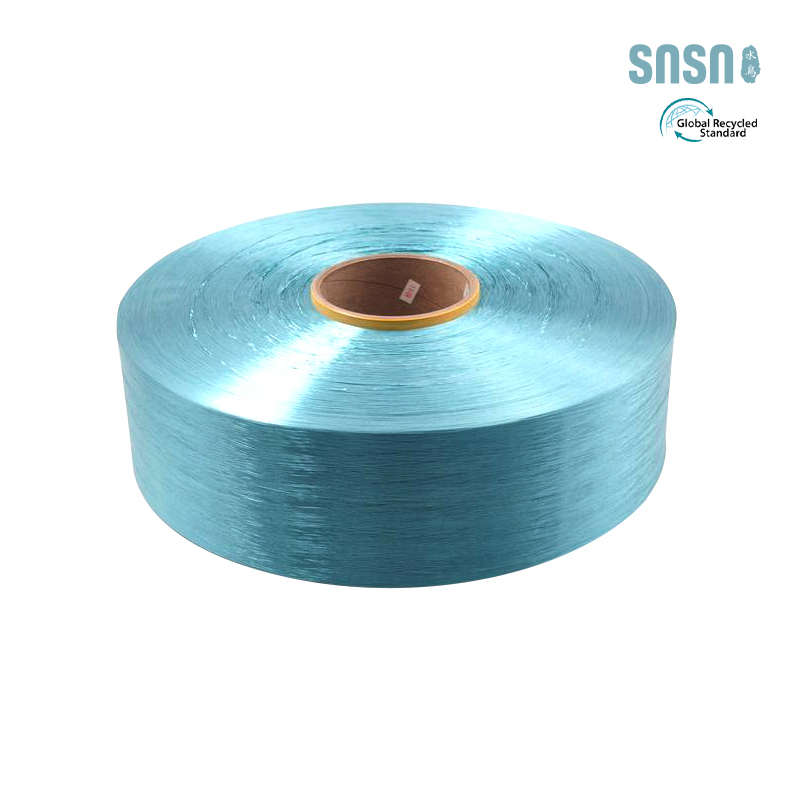

POY yarn is typically derived from polyester, produced through a precise melt-spinning process that yields a semi-oriented fiber with moderate molecular alignment. This unique structural characteristic positions it as an intermediary product—neither fully drawn nor completely amorphous—but rich with latent capabilities. It serves as a blank canvas, ready to be enhanced through further processing such as drawing, texturing, or twisting.

The real power of POY lies in its versatility. Once subjected to post-spinning treatments like drawing, it evolves into what’s known as DTY (Drawn Textured Yarn) or FDY (Fully Drawn Yarn), each offering distinct tactile and functional properties. These transformations unlock enhanced tensile strength, improved resilience, and a softer hand feel, making the end products suitable for a wide array of applications—from sportswear and lingerie to industrial fabrics and home textiles.

What sets POY apart in the competitive landscape of synthetic fibers is its cost-effectiveness combined with performance potential. Manufacturers favor it for its efficiency in downstream processing, allowing flexibility in fabric design without compromising on quality. Whether woven, knitted, or blended with other fibers, POY-based textiles deliver consistent results, making them a staple in both mass production and niche textile engineering.

From a technical standpoint, POY's low crystallinity and high extensibility make it ideal for applications requiring deformation resistance and dimensional stability after thermal treatment. This means garments and materials made from POY-derived yarns maintain their shape and integrity even under stress, a critical factor in performance-driven apparel and durable goods.

Moreover, as sustainability becomes increasingly integral to textile innovation, POY offers a compelling advantage. Its production can be optimized for energy efficiency, and when sourced from recycled polyester feedstock, it contributes to circular economy goals without sacrificing functionality.

POY yarn may not always be the final product seen by consumers, but it plays a pivotal role behind the scenes. It is the unsung workhorse of modern textile creation—an enabler of comfort, durability, and design sophistication. For manufacturers aiming to balance innovation with practicality, POY remains an indispensable asset in the evolving narrative of fabric technology.

English

English عربى

عربى Türk

Türk Español

Español